The store will not work correctly in the case when cookies are disabled.

Menu

Cleanroom HVAC,Cleanroom HVAC

DA 2400N Desiccant Dehumidifier, 44.1 lbs/hr Drying Capacity, Condair, 480 V

- DA 2400N Desiccant Dehumidifier with a drying capacity of 44.1 lbs. per hour

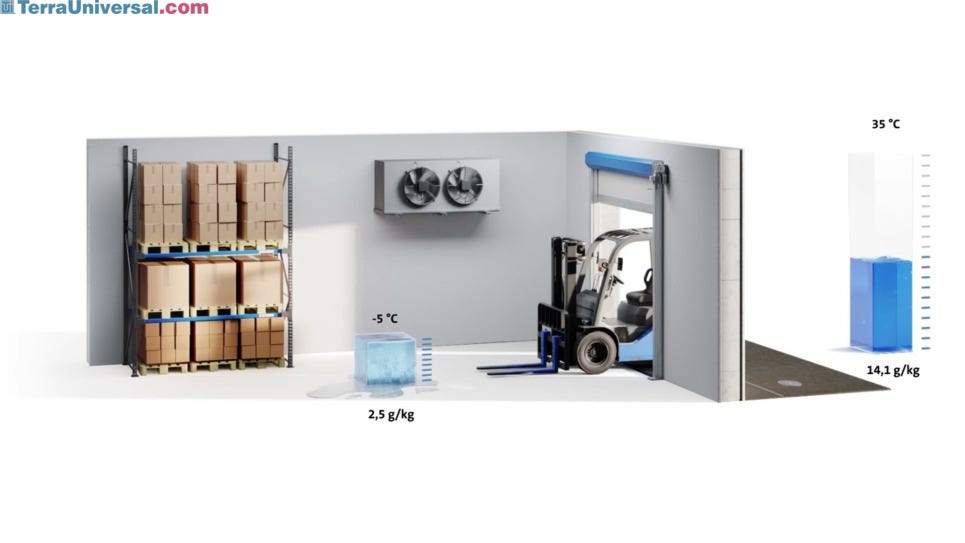

- For use in extremely low temperature environments and extremely low humidity requirements of 10 - 20% RH

- Non-flammable and silicone-free sorption rotor brings humidity values down to a minimum at temperatures as low as -22°F (-30°C)

- Speak to a Terra Product Specialist about your required configurations

- Features: double-wall housing, comprehensive controller, highly-efficient desiccator rotor, efficient fans, regenerative heat sources, service-friendly construction

• Capacity lb/hr: 44.1 lbs/hr

• Manufactured by: Condair

• Model: DA 2400N

• Process Air Flow: 2354 CFM

• Unit of Measure: EA

Read more

Warranty: Two-Year Manufacturer Warranty After Installation

Summary

- DA 2400N Desiccant Dehumidifier with a drying capacity of 44.1 lbs. per hour

- For use in extremely low temperature environments and extremely low humidity requirements of 10 - 20% RH

- Non-flammable and silicone-free sorption rotor brings humidity values down to a minimum at temperatures as low as -22°F (-30°C)

- • Speak to a Terra Product Specialist about your required configurations

- • Features: double-wall housing, comprehensive controller, highly-efficient desiccator rotor, efficient fans, regenerative heat sources, service-friendly construction

- Industry Applications: cleanrooms, pharma, food processing and storage, electronic, military equipment storage, museums and archival storage

- Desiccant dryer fitted with durable AISI 304 stainless steel

- Completely UL Certified

- Fiber optic desiccant rotor with honeycomb structure and coated with extremely hygroscopic silica gel

- Specifications of DA 2400N Desiccant Dryer

- Nominal process air volume: 2354 CFM

- Nominal regeneration air volume: 500 CFM

- Ext. compression — process air: 0.8 (in H2O)

- Ext. compression — regeneration air: 0.8 (in H2O)

- Regeneration heater power: 23 kW

- Process air connection diameter in (mm): 15.7 (400)

- Dry air connection diameter in (mm): 12.4 (315)

- Humid/regeneration air connection diameter in (mm): 7.9 (200)

- Sound pressure dB: 69

- Features:

- Double-wall housing: fully-insulated models constructed with corrosion resistant Aluzinc® with powder coating, housing space filled with 1.25"mineral wool insulation

- Comprehensive controller: adsorption desiccant dryers feature PLC with touch screen display for setting and viewing of humidity control, monitors internal components for increased operational reliability, and alarm

- Maintenance-free desiccant rotor: hygienic, non-flammable and non-respirable adsorption rotors feature a honeycomb structure coated with an extremely hygroscopic silica gel; enormous internal surface provides efficient moisture transmission

- Efficient EC fans: regeneration process with push configuration directs air over the desiccant rotor with positive pressure for problem-free use even at very low humidity levels, fans do not come into contact with hot moist air from desiccant rotor for problem-free use; features fan speed adjustment and flexibility between process and reactivation air

- Regenerative heat sources: features electrical PCT heating elements, and self-regulating properties protect against fusing and thermostat interruptions

- Service-friendly construction: easy-to-remove components and filter inserts, vertically arranged rotor for low overall height, and optimum load distribution of installed components ensure long service life and high operation reliability

- Standard models fitted to pre and/or post cooling additions, PTC heaters (configured for staged modulation)

- Can be configured per request

Specifications

• Capacity lb/hr: 44.1 lbs/hr

• Manufactured by: Condair

• Model: DA 2400N

• Process Air Flow: 2354 CFM

• Unit of Measure: EA

• Dimensions, Product: 48" W x 39" D x 36" H

• Dimensions, Shipping: 54" W x 45" D x 42" H

• Electrical Specifications: 480 V, 3 Ph, 60 Hz

• Weight, Product: 452 lb

Other products you may find relevant