- +1 (714) 578-6100

Hours Mon - Fri, 07:00 AM - 06:00 PM (Pacific Time)

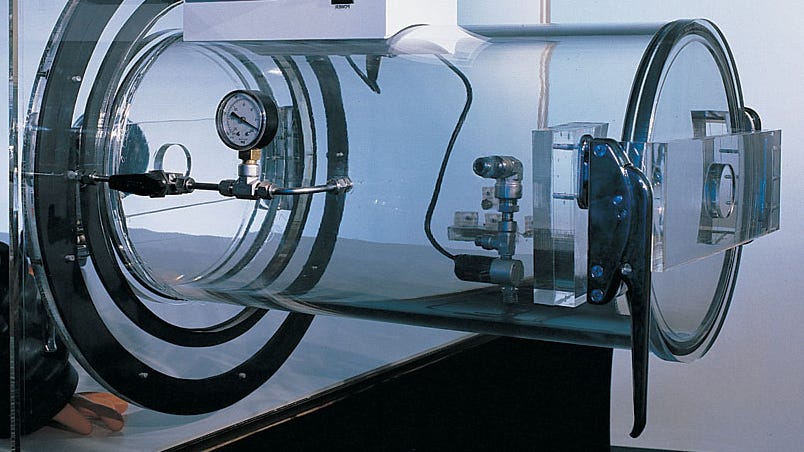

Vacuum Chambers

-

Posted: May 15, 2024Categories: Vacuum ChambersRead more »

Vacuum chambers for outgassing and degassing applications must consider the rate and volume of gas released from materials when placed in a vacuum. Outgassing rates can be critical as it might lead to contamination of other surfaces, optical degradation, or material failure in vacuum or space environments.

-

Posted: May 15, 2024Categories: Vacuum ChambersRead more »

As an American manufacturer of vacuum chambers and their associated systems, Terra Universal offers an array of vacuum chamber designs for material testing, thermal testing, stress testing, degassing, atmospheric simulation, and more. In this series, we'll discuss smaller benchtop vacuum chambers for small parts, as well as large high-capacity vacuum chamber models for extra large assemblies or components.

-

Posted: May 15, 2024Categories: Vacuum ChambersRead more »Thermal Vacuum Testing subjects materials or equipment to both vacuum conditions and extreme temperatures, both hot and cold. These tests evaluate material and component performance between ambient and operational temperatures. Aerospace components and space vehicles may require more extreme simulations that reproduce hot-to-cold cycles experienced by a craft that is entering or exiting a planetary atmosphere. Importantly, these tests help researchers understand the combined effects of temperature and pressure values over short cycles or longer sustained periods.

-

Posted: May 14, 2024Categories: Vacuum ChambersRead more »As an American manufacturer of vacuum chambers and their associated systems, Terra Universal offers an array of vacuum chamber designs for material testing, thermal testing, stress testing, degassing, atmospheric simulation, and more. In this series, we'll discuss smaller benchtop vacuum chambers for small parts, as well as large high-capacity vacuum chamber models for extra large assemblies or components. Additionally, we'll discuss configurable add-ons such as vacuum pumps, vacuum control modules, vacuum gloveboxes, and vacuum chamber material selection criteria. Whether it's a lab, cleanroom, or unspecified research environment, Terra offers thousands of ready-to-ship products, as well as custom-fabricated solutions for unique applications.

-

Posted: April 11, 2023Read more »

A vacuum chamber is a sealed container that creates a localized, low-pressure environment. Vacuum chambers and vacuum gloveboxes are used in a variety of applications including scientific research, manufacturing, product development, performance testing, and simulation environments. Vacuum chamber applications include, but are not limited to, leak testing, stress testing, semiconductor failure analysis, degassing, drying, distillation, permeability testing, coating, specific gravity determination, atmospheric simulations, and inert gas storage.

-

Posted: February 19, 2020Read more »

Terra offers desiccator and desiccator cabinet designs for every purpose - whether it be for transportation, short term or long term storage, these dry cabinets protect sensitive parts and materials of all shapes and sizes from moisture damage, particle contamination, electro-static discharge, and more. Find out which design best fits your needs!

-

Posted: May 31, 2016Categories: Vacuum ChambersRead more »

Vacuum Overview

“Vacuum” means the complete absence of matter. In order to create vacuum conditions, pressure within a given space must be lower than the surrounding environment. The quality of the vacuum is dependent upon several factors, including the number of particles within a given space. The inertia of moving particles exerts pressure, so fewer particles means lower pressure. Scientists have given up on the idea that a perfect vacuum is even possible; space is the most ideal vacuum we know of, but hydrogen atoms, energy waves and other moving particles are still present.

Vacuum Chambers

Imperfect as they are, we create vacuums for various applications and processes: sealed chambers that help researchers and manufacturers with tasks including leak testing, stress testing, degassing, drying, distillation, permeability testing, coating, specific gravity determination,